Decoding Durability: Why 18-Gauge Stainless Steel is the Commercial Prep Standard

October 03, 2025

Write a comment

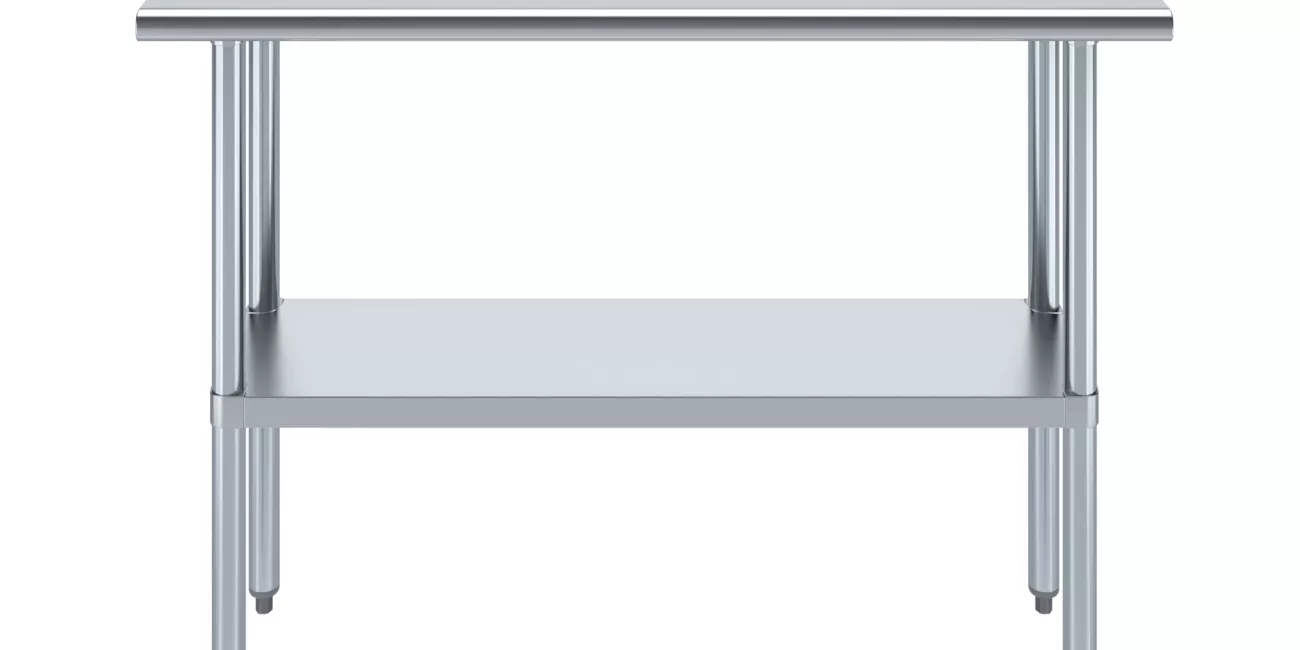

When outfitting a commercial kitchen, laboratory, or industrial workspace, stainless steel work tables are the undisputed foundation. But stainless steel isn't a one-size-fits-all material. Its durability, strength, and price are fundamentally determined by its gauge, or thickness. Understanding the role of 18-gauge stainless steel is critical to making a cost-effective and compliant purchasing decision.

This guide, brought to you by the manufacturing experts at AmGood Supply, breaks down why 18-gauge steel remains the industry benchmark.

What is 18-Gauge Stainless Steel Thickness?

The term "gauge" refers to the thickness of the metal sheet. Counterintuitively, the lower the gauge number, the thicker the steel.

For instance, 16-gauge steel is thicker and heavier than 18-gauge steel.

• How thick is 18-gauge stainless steel? While thickness can vary slightly depending on the manufacturing standard (such as the American Wire Gauge system), 18-gauge stainless steel thickness typically corresponds to approximately 1.27 millimeters (0.05 inches).

For comparison, a heavy-duty option often demanded for extremely busy environments might utilize 16-gauge steel, which is approximately 1.59 mm thick.

Is 18-Gauge Stainless Steel Good for Commercial Use?

Yes, 18-gauge stainless steel is good and, in many cases, is the industry standard for commercial prep and work tables. This is due to an ideal balance between durability, weight, and cost:

- The question of which is better, 16 or 18 gauge stainless steel, depends entirely on the intended application and volume of work. Generally, the lower the gauge number, the thicker the steel.When making a purchase decision for commercial prep tables, consider the following differences in performance, weight, and cost:

- 18-Gauge Stainless Steel (The Industry Standard)

- 18-gauge stainless steel is the standard choice for most commercial environments, offering an optimal balance of strength and cost-effectiveness.

- • Durability & Strength: This gauge provides sufficient strength for most light-to-medium volume preparation and serving areas.

- • Weight: Tables made from 18-gauge steel are lighter and easier to move or install.

- • Cost: This is a more cost-effective option, offering a better balance of price and performance.

- • Key Advantage: The 18-gauge material provides the necessary hygiene and corrosion resistance expected of stainless steel in commercial food service, while keeping the cost of the finished product accessible.

16-Gauge Stainless Steel (The Heavy-Duty Option)

16-gauge steel is thicker than 18-gauge and is reserved for more demanding applications.

- Durability & Strength: This material offers superior durability and is designed for extremely heavy equipment or continuous, vigorous processing.

- Weight: 16-gauge units are heavier, typically used in fixed installations.

- Cost: This is a higher cost material, reserved for specific high-impact needs.

- Decision Guide:

- Choose 18-Gauge If: You need tables for general food prep, light assembly, storage, or for areas that are not subject to intense stress, vibration, or extremely heavy machinery.

- Choose 16-Gauge If: Your table will support heavy equipment

The question of which is better, 16 or 18 gauge stainless steel, depends entirely on the intended application and volume of work.

• Choose 18-Gauge If: You need tables for general food prep, light assembly, storage, or for areas that are not subject to intense stress, vibration, or extremely heavy machinery. It is the perfect choice for most standard commercial prep tables.

• Choose 16-Gauge If: Your table will support heavy equipment (such as mixers or fryers), will endure constant abuse, or is required for heavy industrial assembly where superior load-bearing capacity is the priority.

As a rule, for environments where budget and versatility are key, 18-gauge stainless steel tables offer the best value without compromising essential commercial standards.